Let’s delve into the world of plastic recycling, explore the limitations of traditional methods, and discover the exciting potential of these new technologies. Plastic, It’s ubiquitous in our lives, from the packaging of our groceries to the clothes on our backs. But its very convenience creates a massive environmental problem: plastic waste. While traditional mechanical recycling has been the mainstay for decades, the industry is undergoing a transformation with innovative “advanced recycling” processes emerging.

Table of Contents

The Traditional Recycling Workhorse: Mechanical Plastic Recycling

For years, mechanical recycling has been the backbone of the plastic recycling industry. Here’s a breakdown of the process:

- Sorting: The first step involves separating different types of plastics. This can be done manually or with sophisticated automated sorting technologies that use near-infrared (NIR) spectroscopy to identify plastic types based on their chemical structure.

- Washing and Cleaning: Once sorted, the plastics are washed and shredded to remove contaminants like dirt, food residue, and labels.

- Melting and Repelletization: Cleaned plastic flakes are melted and extruded into pellets, which can then be used to manufacture new plastic products.

While this process offers a valuable solution, it has limitations.

- Limited Recyclability: Not all plastics are created equal. Mechanical recycling is most effective for certain types, typically PET (used in beverage bottles) and HDPE (used in milk jugs and detergent bottles). Other plastics, like mixed-plastic films or polystyrene (used in takeout containers), pose challenges due to their complex structures or difficulty in sorting them efficiently.

- Downcycling: During mechanical recycling, the plastic degrades slightly with each processing cycle. This means recycled plastic often ends up in lower-quality applications compared to virgin plastic. For example, recycled PET bottles might be turned into fleece jackets instead of new bottles.

These limitations have spurred the development of advanced recycling technologies that aim to overcome these challenges.

Dawn of a New Era: Advanced Plastic Recycling Technologies

Advanced recycling encompasses a range of innovative processes that break down plastic waste into its basic building blocks – chemical feedstocks – or even convert it into new, high-quality plastic. Here are some of the most promising technologies:

- Chemical Recycling: This category encompasses several processes that use heat, pressure, or solvents to break down plastic polymers into their chemical building blocks (monomers) or smaller molecules (oligomers). These can then be used to create virgin-quality plastic or other valuable chemicals. Common techniques include:

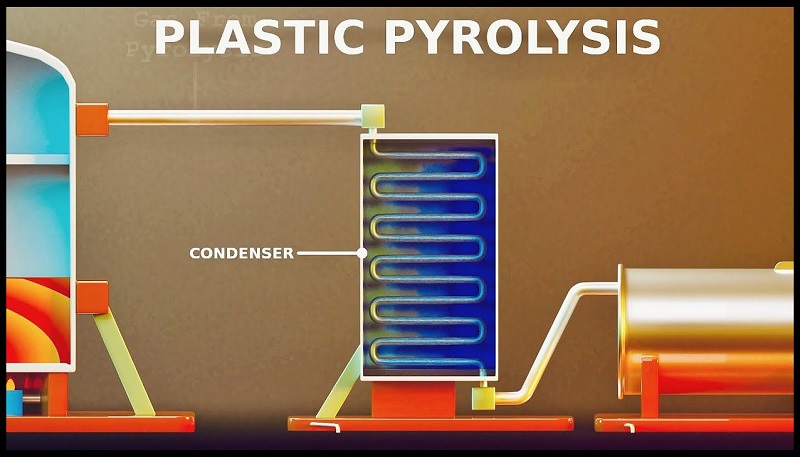

- Pyrolysis: Plastic waste is heated in an oxygen-free environment, breaking it down into liquids (oil), gases (including valuable chemicals like hydrogen), and char (usable as fuel).

- Gasification: Similar to pyrolysis, but with a controlled amount of oxygen, converting plastic waste into a combustible gas (syngas) that can be used for energy production or further processed into chemicals.

- Depolymerization: Uses specific catalysts or solvents to break down plastic polymers back into their original monomers. These can then be directly used to create virgin-quality plastic.

- Dissolution Recycling: This process dissolves plastic waste in a solvent, separating valuable plastic polymers from contaminants. The cleaned plastic can then be repolymerized into high-quality plastic.

A Deep Dive into Advanced Recycling

As these technologies are still evolving, several questions arise:

- Is advanced recycling more environmentally friendly? The answer depends on the specific technology and how the energy is sourced. Some processes require significant energy input, which can impact their environmental footprint. However, ongoing research aims to optimize these processes and utilize renewable energy sources.

- Can advanced recycling handle all types of plastic waste? Advanced recycling has the potential to address a wider range of plastics compared to mechanical recycling. However, some technologies might not be suitable for all types of plastic yet. Ongoing research is expanding their capabilities.

- What are the economic considerations? Advanced recycling technologies are still in their early stages of development, and setting up these facilities requires significant investment. As the technology matures and economies of scale come into play, costs are expected to decrease.

A Future Where Plastic Becomes a Resource, Not Waste

The emergence of advanced recycling offers a ray of hope in tackling plastic pollution. Here’s what the future holds:

- Improved Sorting Technologies: Advanced sorting techniques using artificial intelligence and multi-sensor technology will improve the efficiency of separating different plastic types, making it easier to utilize them in both mechanical and advanced recycling processes.

- Integration of Technologies: A combination of mechanical and advanced recycling might prove most effective. For instance, mechanical recycling can be used for easily recyclable plastics, while advanced recycling tackles more complex waste streams.

- Policy and Infrastructure Development: Government policies that incentivize advanced recycling alongside investments in infrastructure development are crucial for wider adoption. Extended Producer Responsibility (EPR) schemes, where manufacturers are held responsible for the end-of-life management of their products, can also play a significant role.

- Consumer Education: Public awareness about responsible plastic consumption and proper waste disposal is vital. Educating consumers about the different types of plastics and which ones are truly recyclable can significantly improve recycling efficiency.

- Collaboration and Innovation: Collaboration between researchers, industry players, and policymakers is essential to accelerate the development and implementation of advanced recycling technologies. Investment in research and development will be key to overcoming technical challenges and making these processes more cost-effective.

The journey towards a circular plastic economy, where plastic is treated as a valuable resource and not waste, requires a multi-pronged approach. By combining traditional mechanical recycling with the potential of advanced recycling technologies, alongside robust policy frameworks and consumer education, we can create a future where plastic pollution becomes a thing of the past.

However, challenges remain. Public perception of some advanced recycling technologies like pyrolysis needs to be addressed. Concerns surrounding potential emissions and proper waste management of byproducts need to be effectively communicated. Additionally, ensuring the safety and environmental soundness of these processes throughout their lifecycle is crucial.

Despite these challenges, the potential benefits of advanced recycling are undeniable. By embracing innovation, fostering collaboration, and implementing responsible policies, we can turn the tide on plastic pollution and create a more sustainable future for our planet.

US Companies in Advanced Plastic Recycling

The United States is home to several innovative companies at the forefront of advanced plastic recycling technologies. Here’s a glimpse into some of the key players, along with publicly available information on their market capitalization (as of April 30, 2024) and recent financial performance (data might not be available for all companies):

1. The Coca-Cola Company (KO):

- Market Capitalization: ~$240 Billion

- Recent Sales (2023): ~$48 Billion

- Profit Margin (2023): ~26%

Coca-Cola, a beverage giant, is actively involved in promoting plastic recycling. They have set ambitious goals for using recycled content in their packaging and invest in initiatives like the World Wildlife Fund’s “Rethink Plastic” partnership to improve waste collection and recycling infrastructure globally. While Coca-Cola itself isn’t a plastic recycler, their focus on using recycled materials strengthens the demand for recycled plastic feedstock.

2. Dow Inc. (DOW):

- Market Capitalization: ~$57 Billion

- Recent Sales (2023): ~$55 Billion

- Profit Margin (2023): ~11%

Dow, a major chemical company, is actively developing and investing in advanced recycling technologies. A major materials science company. Their initiatives include Project REPLAY, which utilizes chemical recycling to convert plastic waste back into high-value feedstocks for new plastic production. Their initiatives include:

* **Project REpurpose:** Aims to convert used plastic into new, high-quality plastic feedstock through a chemical recycling process.

* **Collaboration with Mura Technology:** Partners with Mura, a company pioneering a revolutionary hydrothermal catalytic recycling (HCR) technology that breaks down plastic into its basic building blocks for reuse.3. ExxonMobil Corporation (XOM):

- Market Capitalization: ~$340 Billion

- Recent Sales (2023): ~$376 Billion

- Profit Margin (2023): ~34%

ExxonMobil, an oil and gas giant, is also exploring advanced recycling technologies. This oil and gas giant is investing in advanced recycling technologies like pyrolysis. Their efforts focus on converting plastic waste into valuable resources like transportation fuels and chemical feedstocks. Their focus areas include:

* **ExxonMobil Advanced Recycling (EMAR):** Developing a proprietary technology to convert plastic waste into high-value chemical feedstocks.

* **Alliance with LyondellBasell:** Partnering with another major chemical company to develop and commercialize advanced plastic recycling technologies.4. PepsiCo Inc. (PEP):

- Market Capitalization: ~$220 Billion

- Recent Sales (2023): ~$80 Billion

- Profit Margin (2023): ~12%

Similar to Coca-Cola, PepsiCo is a beverage leader committed to increasing recycled content in their packaging. They are also investing in recycling infrastructure projects and collaborating with industry partners to improve plastic waste management.

5. Amcor plc (AMCR) (US Subsidiary – Amcor Rigid Plastics):

- Market Capitalization: ~$20 Billion

- Recent Sales (2023): ~$18 Billion (Global) – Specific US figures unavailable

- Profit Margin (2023): ~10% (Global) – Specific US figures unavailable

Amcor, a global leader in rigid plastic packaging, has a strong presence in the US through its subsidiary, Amcor Rigid Plastics. While not directly involved in large-scale plastic recycling, Amcor is focused on design for recyclability, ensuring their packaging is compatible with existing recycling streams. They are also exploring the use of recycled content in their products.

Companies Beyond Beverage Giants and Chemical Leaders:

While the beverage and chemical industries are at the forefront of plastic recycling advancements due to their reliance on plastic packaging and the potential for feedstock production, other US companies are making significant strides in this sector:

6. BASF Corporation (BASFY):

- Market Capitalization: ~$78 Billion (German company, US subsidiary)Recent Sales (2023): ~$25 Billion (Global) – Specific US figures unavailableProfit Margin (2023): ~8% (Global) – Specific US figures unavailable

* **ChemCycling:** This process uses chemical recycling to convert post-consumer plastic waste into high-quality recycled feedstock that can be used to create new plastic products.

7. Mosaic Company (MOS):

- Market Capitalization: ~$12 BillionRecent Sales (2023): ~$10 BillionProfit Margin (2023): ~18%

8. Renewlogy Inc. (Private):

- Market Capitalization (Not Publicly Traded)Recent Sales Figures Unavailable

9. MBA Polymers Inc. (Private):

- Market Capitalization (Not Publicly Traded)Recent Sales Figures Unavailable

10. American Chemistry Council (ACC): While not directly a company, the ACC is a leading trade association representing the American chemical industry. They play a crucial role in advocating for policies that support the development and commercialization of advanced recycling technologies in the US.

11. LyondellBasell Industries (LYB): This global chemical company is exploring advanced depolymerization technologies to convert plastic waste back into its original monomers for virgin-quality plastic production. Market Capitalization: ~$42.1 Billion (Source: Financial news websites)

12. Regen Polymers: This California-based company utilizes a proprietary advanced recycling technology to convert mixed plastic waste into high-quality recycled plastic pellets suitable for various applications. Information on their market capitalization and financials might not be publicly available due to their private company status.

Looking Forward: Transparency and Collaboration are Key

As the plastic recycling industry continues to evolve, transparency and collaboration will be crucial for its success. Companies involved in advanced recycling need to clearly communicate their processes and the environmental impact of their technologies. Furthermore, collaboration between different stakeholders – chemical companies, plastic producers, waste management companies, and policymakers – is essential to develop a robust and efficient plastic recycling infrastructure.

By continuing to invest in research and development, fostering open communication, and working together, the US plastic recycling industry has the potential to become a global leader in creating a more sustainable future for plastic.

It’s important to note that the advanced recycling industry is still evolving, and many companies are in the early stages of development. Financial data for private companies might not be readily available. However, the growing interest from established industry leaders like Dow, ExxonMobil, and LyondellBasell signifies the immense potential of these technologies.

These companies are paving the way for a more sustainable future by developing innovative solutions to address the global plastic waste crisis. Their efforts, coupled with continued research and development, hold the key to transforming plastic from a source of pollution into a valuable resource.

Important Note: It’s important to understand that these companies are at various stages of involvement in the plastic recycling industry. Some, like Dow and ExxonMobil, are actively developing advanced recycling technologies, while others, like Coca-Cola and PepsiCo, are focusing on increasing the use of recycled content in their products and supporting broader recycling initiatives.

Latest FAQs on Plastic Recycling and Advanced Recycling Technologies:

1. What are the limitations of traditional mechanical recycling?

- Limited recyclability: Not all plastics are created equal. Mechanical recycling is most effective for certain types, like PET and HDPE.

- Downcycling: Recycled plastic degrades slightly with each processing cycle, often ending up in lower-quality applications.

2. What are the benefits of advanced recycling?

- Handles a wider range of plastics: Advanced recycling can potentially tackle more complex plastics than traditional methods.

- Higher quality recycled plastic: Some advanced recycling processes can create virgin-quality plastic feedstock.

3. Is advanced recycling more environmentally friendly?

- The answer depends on the specific technology and energy source. Some processes require significant energy input. Ongoing research aims to optimize these processes and utilize renewable energy.

4. What are some popular advanced recycling technologies?

- Chemical Recycling: Breaks down plastic into its chemical building blocks for reuse. Examples include pyrolysis, gasification, and depolymerization.

- Dissolution Recycling: Dissolves plastic waste in a solvent to separate valuable plastic polymers from contaminants.

5. What are the challenges with advanced recycling technologies?

- Cost: These technologies are still in their early stages and require significant investment for setup.

- Public perception: Concerns exist regarding potential emissions and byproducts. Clear communication is key.

6. How can consumers help improve plastic recycling?

- Reduce plastic consumption: The best waste is the waste we don’t create!

- Recycle properly: Check local guidelines for acceptable plastics and ensure they’re clean.

- Support companies using recycled content: Creates a market demand for recycled plastic.

7. What’s the future of plastic recycling?

- A combination of improved sorting technologies, integration of mechanical and advanced recycling, and robust policy frameworks is likely.

- Public education and consumer behavior changes are crucial for success.

8. Are there any safety concerns with advanced recycling facilities?

- As with any industrial process, safety is paramount. Proper regulations and monitoring are essential.

9. What role can governments play in promoting plastic recycling?

- Policies like Extended Producer Responsibility (EPR) can incentivize responsible plastic management.

- Investment in recycling infrastructure and research & development is crucial.

10. Where can I learn more about plastic recycling and advanced recycling technologies?

- Websites of reputable organizations like The American Chemistry Council (ACC), The Association of Plastic Recyclers (APR), and Ellen MacArthur Foundation offer valuable resources.

- Government agency websites like the US Environmental Protection Agency (EPA) provide information on plastic waste management.

Conclusion:

The battle against plastic pollution demands a multifaceted approach. Advanced recycling technologies offer a promising new weapon in this fight. While these technologies are still evolving, they hold immense potential to revolutionize plastic waste management. By combining them with traditional mechanical recycling, robust policy frameworks, and responsible consumer behavior, we can create a future where plastic is no longer a burden, but a valuable resource. The journey ahead requires continued research, investment, and collaboration, but the potential rewards are significant – a cleaner planet and a more sustainable future for generations to come.